MORE>

MORE>

On the northern bank of the Shenshui River, the phoenix crown takes shape, reflecting the ice spirit.

By the clear autumn waters of the Hun River, "Yunshang Bingyu" stands gracefully like a lotus emerging from the water. This huge ice structure with a total construction area of 263,800 square meters embodies the concept of "symbiosis between the city and nature" in its steel and concrete framework. Among it, the 135,700-square-meter National Speed Skating Hall outlines the agility of the Hun River with its streamlined curved surfaces. From an aerial view, the roof built by Sanxin Industrial resembles a gold-gilded phoenix crown, shining with the integrated light of technology and art under the northern sun.

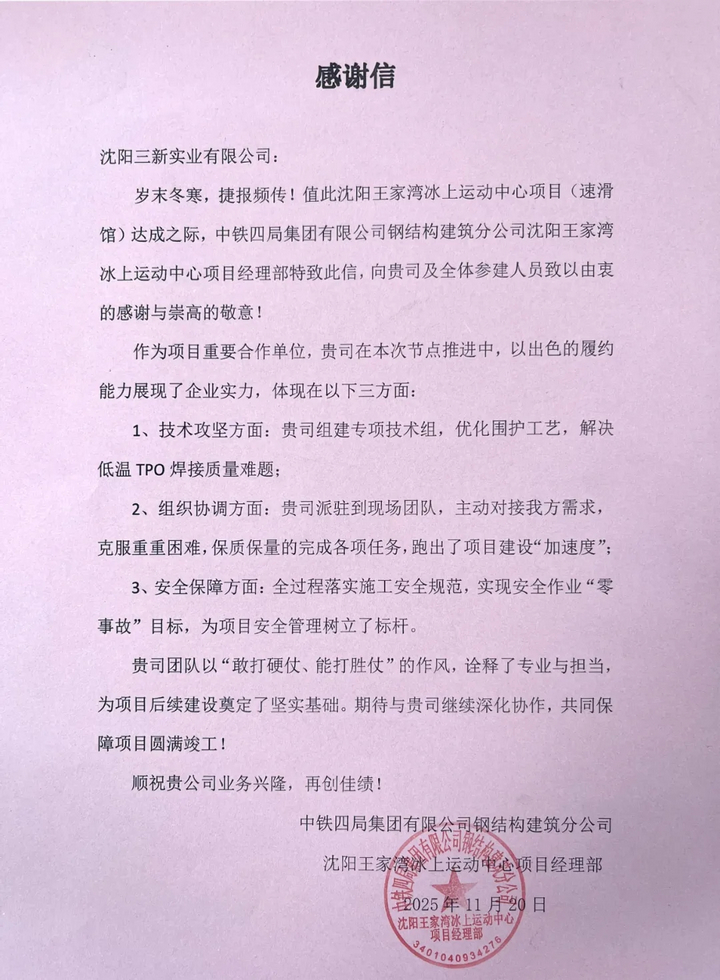

Recently, a letter of thanks from the China Railway Fourth Bureau Project Department arrived during the golden autumn. Every word in it was filled with respect for Sanxin: "Breaking through technical challenges, efficient organization and coordination, and solid safety guarantees have laid a solid foundation for the stadium's scheduled closure with the 'Sanxin strength'." Behind this praise lies the accumulation of sweat and perseverance, and it is also the best interpretation of the craftsmanship and strength of the Northeast construction iron army.

One tile, one world: Deciphering the survival code of ice and snow venues

In the severe winter of Northeast China with temperatures as low as minus 30 degrees Celsius, how can the roof withstand strong winds and heavy snow while also considering thermal insulation, energy conservation, and photovoltaic efficiency? Sanxin Industry's original "metal-fused TPO composite unitized roof system" provides the optimal solution, and with its technical discourse power, it has dominated the direction of the project's core plan.

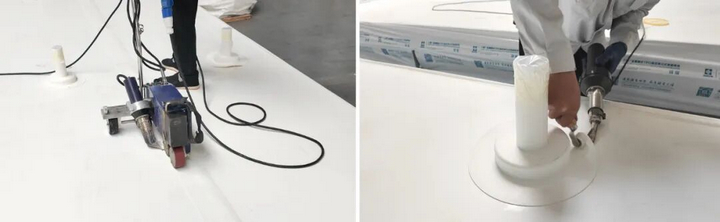

This system is by no means a simple splicing of materials, but an innovative crystallization integrating three core advantages: the innovative metal-fused polymer waterproofing technology and the unique photovoltaic connection mechanism are seamlessly connected, enabling a qualitative leap in waterproofing, thermal insulation, and sound insulation performance, and completely solving the pain point of roof leakage in cold regions; the digital modular unit design breaks through the limitations of traditional construction, decomposing complex roofs into standardized units, laying the foundation for efficient assembly; the revolutionary factory intelligent prefabrication and prefabricated construction mode significantly reduces on-site operations, not only avoiding the risks of rainy season construction, but also ensuring construction accuracy and environmental protection requirements. Its comprehensive performance stands out among many schemes and has become the core blueprint defining the project's roof standards.

From Blueprint to Benchmark: Leading the Scheme Forward with Technical Strength

As a top 30 enterprise in China's steel structure industry and a top 10 enterprise in the metal roof and wall industry, Sanxin has deeply participated in the research, discussion and tackling of roof schemes with the attitude of an industry leader since the project was launched. Faced with the stringent requirements of "Cloud Ice Jade" for the roof system – which must not only match the structural characteristics of the 102-meter-span stringed wooden arch steel frame, but also meet the needs of ultra-low energy consumption and photovoltaic integration – the scheme demonstration stage once fell into intense debate.

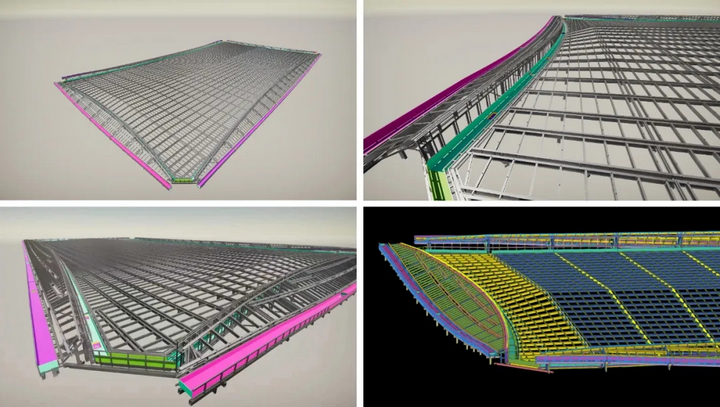

The Sanxin team did not wait passively, but took the initiative to take on technical responsibilities: senior engineers led the team to conduct in-depth on-site surveys, joined forces with technical forces from Tsinghua University, Harbin Institute of Technology and other universities for repeated deductions, and throughout the process, integrated advanced concepts such as modular design, intelligent prefabrication and prefabricated construction. With the help of cutting-edge technologies such as TEKLA and BIM, a visual 3D model was built to accurately calculate the combined efficiency of the 8-layer composite material, and a 1:1 physical sample was used to intuitively present the construction effect and performance advantages.

Among a host of strong competitors, the Sansin team, relying on its profound technical accumulation, innovative problem-solving ideas, and rigorous argumentation process, overcame all objections to lead the finalization of the plan. The 3,000 error-free construction drawings are the best evidence of their professional dedication. This transformation from a "participant" to a "leader" demonstrates Sansin's strong strength and industry responsibility in the field of metal enclosure systems.

From the workshop to the construction site: 78 days of intensive sprint

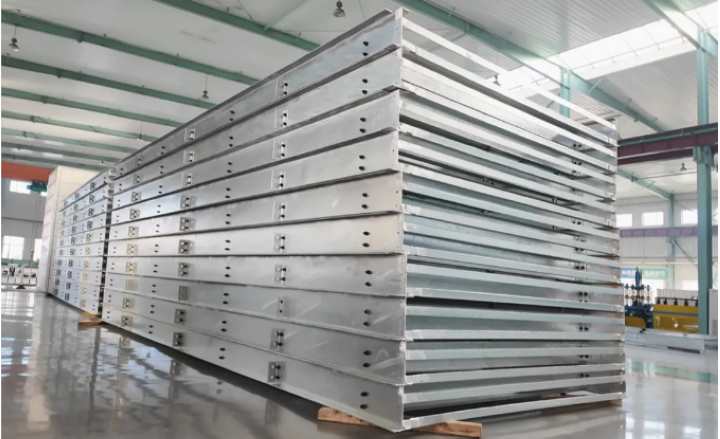

After the main structure was stabilized on August 15, 2025, 786 roof units and 140 gutter units needed to be completed within 78 days during the rainy season. In Sanxin's intelligent workshop, the Italian Salvagnini punching and shearing center and Swiss laser cutting machine operated day and night, breaking down the panels into tens of thousands of parts for precise prefabrication. At the construction site, total stations densely set points to calibrate 3D coordinates, tower cranes steadily hoisted the 9m×3.5m ultra-wide panels, and the warning lines set up by full-time safety officers guarded the "zero-accident" bottom line at a height of 38.4 meters. What is even more amazing is that for the 11 gutters in areas not covered by tower cranes, the technical team innovatively adopted a segmented hoisting process, turning the "impossible" into reality.

From Craftsmanship to Symbiosis: The Wisdom of Embracing Severe Cold

Winter in Northeast China is the greatest challenge. The Three New Special Technology Team optimized the enclosure craftsmanship and overcame the difficulty of low-temperature TPO welding; the drainage gutter is equipped with a precise built-in electric tracing system to eliminate the risk of freezing and blockage; the photovoltaic bracket poles adopt polymer encapsulation components to achieve a seamless connection between waterproofing and power generation. When the simulated strong wind from the wind uplift resistance laboratory sweeps across the roof, this "phoenix crown" proves with data: it is not only the outer garment of the building, but also a close friend of nature.

A group of dream builders form the backbone of Northeast China's revitalization.

The lights that never go out in the design institute late at night, the precise movements of the robotic arms in the workshop every second, and the worn-out and replaced gloves of the on-site workers together outline the spirit of craftsmanship of Sanxin Company, which pursues excellence.

This team, with its "semi-militarized railway gene," safeguards quality through the triple defense line of "self-inspection, specialized inspection, and handover inspection," and catches up with the construction period with the iron army style of "completing the daily plan on the same day." The Supply and Storage Department mapped out transportation routes in advance, and night passes ensured materials arrived on time; the Quality and Safety Department implemented the "first-piece system," and 10-year quality assurance records witnessed the craftsmanship. As China Railway Fourth Engineering Bureau stated in its letter of thanks: "Daring to fight tough battles and being able to win battles, this is the responsibility of Sanxin."

A pure heart, moving from the Hun River to the world stage

The successful completion of the Wangjiawan roofing project is a vivid practice of Sanxin's "intelligent construction + green building" strategy. Sanxin's technologies and achievements have attracted the attention of industry peers and all walks of life, and "Yunshang Bingyu" has become Sanxin's most beautiful business card. As a national prefabricated building demonstration base, this enterprise with a Class-A design institute and a provincial-level technology center has long integrated the original aspiration of "revitalizing the enterprise through science and technology, and serving the country through industry" into its blood. From the CRRC base to the Dalian Heavy Industry Industrial Park, from the Changchun Zhibo project winning the "Jinyu Award" to the Sydney Economic and Trade Fair connecting with the needs of the Brisbane Olympics, Sanxin is enabling Liaoning manufacturing and Chinese technologies to go global.

Hong Aoran, the Executive Director, still has his words in Australia ringing in our ears: "The roofing technology of Wangjiawan is highly aligned with the concept of a Green Olympics." When the photovoltaic panels of "Cloud Ice Jade" absorb the first ray of sunlight, and when the blueprint for overseas cooperation unfolds gradually, Sanxin has proven with actions that buildings can become the crystallization of technology and art, and enterprises can serve as the cornerstone of national rejuvenation.

Beneath the blue-tiled roofs, the future has arrived.

Moonlight sprinkles on the heart of the Hun River, shimmering in harmony with the photovoltaic glow on the roof. This "phoenix crown" forged by Sanxin not only witnesses the preparations for the 2028 Winter Games but also carries the dream of revitalizing the old industrial base in Northeast China.

From the land of Liaoshen to the global stage, Sanxin Industrial is using digital factories as its inkstone and innovative technologies as its brush to write an era-defining answer sheet of "Let architecture empower a better life." And the perseverance hidden in the welds, the wisdom on the blueprints, and the sweat under the starry night will eventually become the most touching footnotes to China's intelligent manufacturing.

Thank you to leaders at all levels, the construction parties, and collaborating units for your trust! Sanxin is willing to embark on the next journey to the stars with you.